5 things to check when purchasing orgonite

Orgonite is a relatively simple material, made of metal shavings, resin, and quartz crystal, so purchasing it should be fairly straight forward. Just enter “orgonite” into your favourite search engine or online marketplace and take your pick. As easy as that, right?

Unfortunately, it’s not quite so simple. Some pieces sold as “orgonite” are not technically orgonite at all. Some vendors don’t even admit to the contents or materials used, let alone photograph them and explain what they do.

Some pieces are deceptively small with basic materials, but are priced high, offering poor value for money. And some pieces are less efficient and effective than others of a similar size.

Most people just want to purchase legitimate orgonite, get a fair processing capacity for the price and grade of the piece, and know exactly what materials it contains.

We’ve put together a list of 5 things to check before purchasing any orgonite:

1. Is the piece actually orgonite?

Fake orgonite. It’s out there, unfortunately. These are normally resin ornaments originating from India, with metaphysical items cast into them, but without the 50/50 matrix of metal shavings and resin needed for it to be classed as orgonite.

Fake orgonite. It’s out there, unfortunately. These are normally resin ornaments originating from India, with metaphysical items cast into them, but without the 50/50 matrix of metal shavings and resin needed for it to be classed as orgonite.

Vendors who are selling such pieces are either purposefully deceiving people by mislabelling their products, or are spamming unrelated keywords to describe the items, or just do not understand what orgonite is.

There may be metaphysical properties, but these will be from the crystals or other materials in the piece. The result is tricking someone into purchasing a resin ornament thinking it’s orgonite when it’s not, further clouding what is already a complicated subject.

Keep your eyes peeled when searching for orgonite, and don’t be fooled by items that don’t have metal shavings visible.

2. The size of the piece, especially in relation to the cost

One of the indicators of processing power for the piece is the physical size. If all other measures are equal, the larger piece will have a higher processing capacity.

One of the indicators of processing power for the piece is the physical size. If all other measures are equal, the larger piece will have a higher processing capacity.

So, while 10 towerbusters (TBs) from one vendor for £15 may seem like a good deal, another vendor offering 10 TBs for £20 will offer better value for money if they are twice the size.

For larger or otherwise important purchases, it may even be worth calculating the volume (if it is not provided), as this will be more accurate for irregular shapes.

Another important note on the subject of size and shape is the thickness or depth of the orgonite piece.

It depends on the density of the metal used, but in general the piece needs to have at least 1cm or ¾ inch of thickness (of a 50/50 mix of metal shavings and resin) in order to function as orgonite.

Orgonite pieces less than 0.5cm or ¼ inch generally don’t have enough of an orgonite matrix to have any meaningful impact. There may be a small local effect, and the metaphysical properties of any other materials included will still be there, but it doesn’t function as conventional orgonite.

Be sure to check the physical size or volume of the pieces in relation to the price, and make sure they are at least 1cm or ¾ inch thick.

3. The type and grade of all materials used

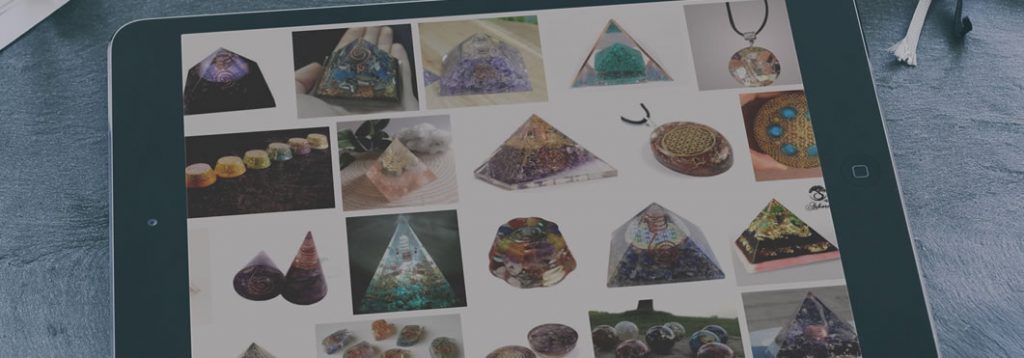

Considering you can’t see inside the finished product, it’s important to know exactly what’s gone into your orgonite. What materials have been used, what grade are those materials, and what are the properties of them?

Considering you can’t see inside the finished product, it’s important to know exactly what’s gone into your orgonite. What materials have been used, what grade are those materials, and what are the properties of them?

At Orgones, we are as transparent as possible – all materials are clearly listed, photographed, and a brief overview of physical properties, metaphysical properties and any relevant history is provided.

The type and grade of the materials used can make a big difference to the function in terms of efficiency and effectiveness, so it’s vital to know exactly what it is you are purchasing.

Check the materials used – there is no reason for a vendor to hide these details. Any attempt to hide or not divulge information about any of the materials used to make orgonite is suspicious.

4. Density and density distribution of the metal

The metal used in orgonite is vitally important. Aluminium is regarded as the standard for making good, strong orgonite. The aluminium we use is 100% pure, clean, and brand new – straight from the metal processing factory.

The metal used in orgonite is vitally important. Aluminium is regarded as the standard for making good, strong orgonite. The aluminium we use is 100% pure, clean, and brand new – straight from the metal processing factory.

A lot of orgonite is made using scrapings, turnings, offcuts, or other by-products of industry. These are commonly contaminated with dust, oil, grease, and other metals or materials. These impurities can impact upon the function, reducing the efficiency.

However, it’s not just the material and purity that’s important, the size and shape of the metal pieces are instrumental in making strong, efficient, effective orgonite.

There needs to be a good mix of sizes (or “densities”) of metal in order to make the piece as efficient as possible for the size. Too much fine, powdery metal seems to reduce the effective range and unbalance the piece. But larger, thicker pieces results in a weaker function and wasted space.

Surface area of the metal is key, the higher the surface area contained within the given volume, the better.

The absolute worst shape of metal to use is round or spherical pieces like ball bearings. These provide the least amount of surface area for the volume of any shape.

At Orgones, we have continually refined and optimised the density of the aluminium to contain as much surface area as possible. According to the metal processing factory, the aluminium we use in a single field grade towerbuster would stretch for 30 feet (9 meters) with a width of 4” (10cm) if it was flattened out.

This is an amazing feat, and only possible because we use an optimal blend of fine, medium and large densities of aluminium, evenly distributed throughout the piece.

Look at the metal portion of the piece and check that there is no wasted space, with a good mix of densities or sizes of metal evenly distributed throughout.

5. Efficient use of space

As mentioned above, too many large metal parts or balls/spheres of metal are examples of inefficient use of space for orgonite pieces.

As mentioned above, too many large metal parts or balls/spheres of metal are examples of inefficient use of space for orgonite pieces.

In addition to these, there is often a “band” of resin at the base. This serves as a barrier between the metal and the base of the piece, stopping sharp metal protruding from the base.

This should be kept to a minimum, as any band or pocket of resin that doesn’t have metal in it is not orgonite – it is just resin.

So a piece with a relatively large band at the base will be less efficient and have less processing power than a piece of the same size with a smaller band.

Check the piece for any sections that appear to be just resin, and keep in mind that sections of just resin are not orgonite. Pieces that do not make efficient use of the available space are less efficient and less effective than those that do.

To summarise…

When purchasing orgonite, be sure to:

When purchasing orgonite, be sure to:

- Check that the piece is actually orgonite

- Check the size of the piece, especially in relation to the cost

- Check the type and grade of all of the materials used

- Look at the density of the metal, and the density distribution

- Evaluate whether the piece is making efficient use of space

If you found this article useful or have any questions, please share it, leave a comment or contact us.

The Field Grade Orgonite mentioned in this article can be found here, and all of our pieces can be found at the homepage here.

Published on: Jun 18, 2018